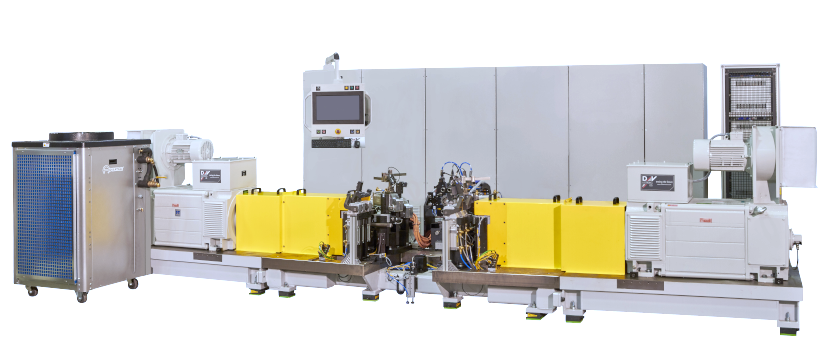

EXL-100 Production Testing

Available configurations include a mechanical torque verification fixture, thermal chamber, liquid chiller and sound and vibration kit.

Features

- Equipped with D&V’s PMM-10 10MHz power analyzer as well as D&V’s SV-PRO software.

- Flexible control scheme supports wide range of e-Axle configuration from single motor with open differential to dual-motor with Dual Power Inverter Module (DPIM).

- The speed of each load motor can be controlled independently to simulate turning or special test requirement such as differential break-in.

- Overall system efficiency of 50% thanks to energy recuperation capability within the system which can reduce energy consumption significantly.

- Automated LV, HV and fluid connections as well as spline engagement whose axial position can be programmed.

- Robot ready and capable of executing the entire EOL test automatically including making electrical and mechanical connections without human intervention and perform air pressure fluid evacuation at the end.

- Pre-programmed comprehensive EOL test which checks not only basic performance of the DUT but also e-Axle specific measurements such as back-lash of the gear train as well as NVH characteristics.

- Part number, test report and statistics file can be selected and queried remotely by MES through TCP/IP.